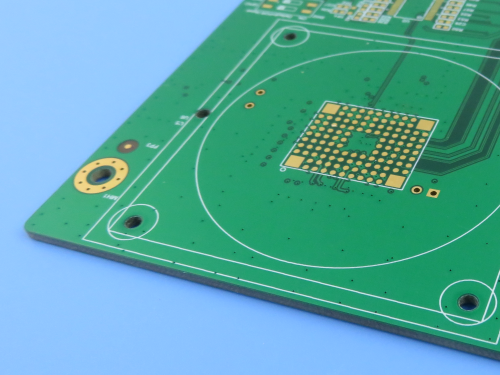

10-Layer HDI Tg180 FR-4 PCB for High Performance

1.Overview of PCB Specifications

| Specification | Details |

|---|---|

| Board Type | 10 layers, N+4+N HDI PCB |

| Material | FR-4 ITEQ IT-180A |

| Solder Mask | Green on both sides |

| Silkscreen Print | White on both sides |

| Surface Finish | ENIG |

| Total Thickness | 1.6mm ± 10% |

| Board Size | 269mm x 213mm (1 PCS) |

| Minimum Hole Size | 0.2mm |

| Solder Mask Thickness | 10um |

| Minimum Dielectric Thickness | 100um |

| Minimum Trace Width | 110um |

| Minimum Spacing | 110um |

| Blind Vias | Yes (L1-L2, L7-L10) |

| Buried Vias | Yes (L2-L8) |

| Via Filling | Type VII filled and capped |

2.PCB Stack-up: 10-Layer Rigid PCB (Component Side on Top)

| Material | Copper Layer | Thickness (um) | Specification |

|---|---|---|---|

| Copper | 1 | 45 | 18um base copper + 17um plating |

| IT-180 PP | Prereg | 100 | IPC-4101/24 |

| Copper | 2 | 18 | |

| IT-180 PP | Prepreg | 160 | IPC-4101/24 |

| Copper | 3 | 18 | |

| FR-4 IT-180 | Core | 200 | IPC-4101/24 |

| Copper | 4 | 18 | |

| IT-180 PP | Prepreg | 160 | IPC-4101/24 |

| Copper | 5 | 18 | |

| FR-4 IT-180 | Core | 200 | IPC-4101/24 |

| Copper | 6 | 18 | |

| IT-180 PP | Prepreg | 160 | IPC-4101/24 |

| Copper | 7 | 18 | |

| FR-4 IT-180 | Core | 100 | IPC-4101/24 |

| Copper | 8 | 18 | |

| IT-180 PP | Prepreg | 160 | IPC-4101/24 |

| Copper | 9 | 18 | |

| IT-180 PP | Prepreg | 100 | IPC-4101/24 |

| Copper | 10 | 45 | 18um base copper + 17um plating |

3. PCB Statistics

Components: 281

Total Pads: 381

Through Hole Pads: 145

Top SMT Pads: 140

Bottom SMT Pads: 96

Vias: 3051

Nets: 10

4.ARTWORK AND QUALITY

Type of Artwork Supplied: Gerber RS-274-X

Quality Standard: IPC-Class-2

Availability: Worldwide

5.Introduction to IT-180

IT-180ATC is a high Tg (175°C by DSC) multifunctional filled epoxy known for its thermal reliability and CAF resistance, suitable for various PCB applications, and can withstand lead-free assembly at 260°C.

6. Key Features of IT-180

High Tg of 175°C

Dielectric Constant: 4.4 @ 10GHz

Dissipation Factor: 0.015 @ 10GHz

Low CTE on X/Y Axis: 11-13 ppm/°C, 13-15 ppm/°C

High Thermal Reliability: T266 >60 minutes; T288, 20 minutes

Excellent CAF Resistance

Improved Z-Axis Thermal Expansion

Lead-Free

UL 94 V0 Flammability Rating

7. Typical Applications

Automotive (Engine Room ECU)

Backplanes

Data Storage

Server and Networking

Telecommunications

Power Boards